Finger joint wood combines short bits of wood to frame more considerable length units. The joint is made of a few cross-section wedges or “fingers” of wood in two contiguous pieces and is held with a stick. Finger-joined timber is utilized for both primary and non-underlying items.

Generally, vertical studs are used for private stage outlines (as a replacement for customary-sized stumbles) and paste overlaid lumber production. Non-structural services include molding and trim.

Popular Types of Wood Joints

- Joinery

- Bisquit

- Box joint

- Bridle joint

- Butt joint

- Clamping wood

- Dado, trench joints

- Dovetail

- Dowels

- Finger joint

- Halved / Cross lap

- Lap joint

- Mitre joints

- Mitre lap joint

- Mortise & tenon

- Pocket holes

- Rabbet joints

- Scarf joint

- Spoke dowels

- Tongue and groove

However, we will discuss the Finger Joint wood’s advantages and disadvantages today.

Finger Joint Pros

- Strength: The strength of finger joint wood is acceptable, and the finger joint is more grounded than regular measurement blunders.

- Stability: The stability of the finger joint is less likely to distort and contort.

- Straightness: The bits of finger joint wood pieces are straight and valid. Any hoodlum and forehead are caught up in the joint wood.

- Consistency: It comprises little bits of top-notch wood, guaranteeing the finished result is consistent with premium quality.

To sum it up, finger joint wood:

- It makes a straighter joint

- Less wood gets wasted during manufacturing.

- Cost-Effective

- Durable for a vertical load

- Adhesives can be applied to create a stronger joint than mortise and tenon.

Finger Joint Wood Cons

- Sturdy: The finger joint wood isn’t as tough as the other wood-like pinnacle wood and needs to be restored after a brief timeframe.

- Water-Damage: The finger joint wood can undoubtedly be harmed by water since it’s anything but a water-obstruction wood, so take significant consideration of it.

Moreover, Finger Joint wood:

- Can come out crooked

- Harder to achieve a smooth wall

What is a Finger Joint wood used for?

Finger-Joint board door frame

Finger joint wood entryways are made utilizing overall quality 100 %seasoned wood. Finger-joint board entryway outline guarantees sturdiness.

These 100% wood joint entryways ensure no development or distorting issues. They can supply all substantial wood entryways pre-hung in their edges for simple establishment.

Finger Joint uses – Flooring.

Finger jointed hardwood flooring is a common wood floor style in East Asia and Europe. Finger joint strong wood floor.

It was delivered by choosing little wood strips of 45-85mm in width—250 mm-750 mm in length in standard and joint overall wood flooring section by uncommon gear.

The favorable position of finger joint flooring is that crude lumber material can be utilized, and less wood board offcut happens.

In any case, finger jointed wood flooring plank is substantially more steady in high rush hour gridlock zones.

On the other hand-warming ground because of the flooring section. Moreover, it has less inward pack power, contrasting with a conventional single hardwood board.

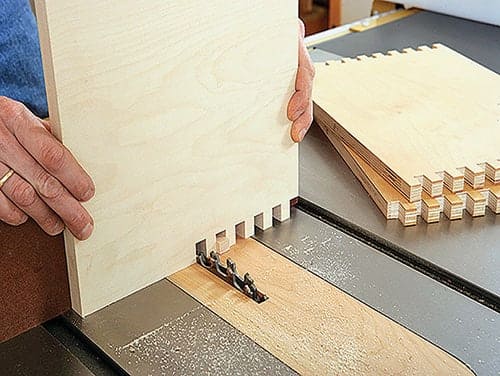

Finger Joint Wood Boxes

A joint finger box is an excellent approach to combining sheets because there are many surface regions for sticking. In addition, it looks extraordinary on your undertakings.

There is a great deal of astounding movable dances you can purchase. Or, again, construct that will permit you to make box joints of every unique size.

Furthermore, if you plan on making a LOT of undertakings with box joints, a committed machine bodes well. In any case, you need to make an incidental box joint in this article and video.

I’ll show you the most straightforward approach to making box joints without building a muddled dance.

Box joints are a solid, durable, and alluring choice for dovetail joints. While a through dovetail joint is more grounded than a case joint, it’s additionally more convoluted to make.

Yet, as you’ll find in the accompanying advances, it is impeccably fitting. A clean box joint is easy to make with a basic box joint dance for your table saw.

You May Also Like the following:

- Best Tarp For Outdoor Furniture (Waterproof)

- 3 Best Stain For Outdoor Wood Furniture

- Decorating Above Kitchen Cabinets With High Ceilings

Is a Finger Joint Wood Strong?

The cross-section of the joint resembles the interlocking of fingers between two hands. Accordingly, the name “finger joint” Each profile side increases the surface area for gluing, resulting in a stronger bond that is more robust than a butt joint but not very visually appealing.

The answer to this question is that a finger joint wood is not particularly strong, as it is not very thick. Therefore, if the finger joint is damaged, it will likely be broken or fractured.